Publications IPH Magazine Revista IPH Nº17 Spatial flexibility and extensibility in hospitals designed by João Filgueiras Lima

- IPH Magazine #17

- COVID-19 pandemic and the trends in healthcare design: insights from the "Decalogue for Resilient Hospitals"

- Healthcare closer to people: A qualitative study of a Swedish reform on healthcare delivery

- Spatial flexibility and extensibility in hospitals designed by João Filgueiras Lima

- Design Insights from a Research Initiative on Ambulatory Surgery Operating Rooms in the U.S.

- A study on the development of the concept growth and change on hospital architecture in Japan

- A study on hospital infection control through architecture in 1980: Chapecó Regional Hospital case study

- Natural ventilation for hospitalization environments: historical aspects

- Hospital architecture and its propositions for beginners and experts

Spatial flexibility and extensibility in hospitals designed by João Filgueiras Lima

Haroldo Pinheiro

Abstract

The detailed study of multiple elements constituting a building is a constant practice in the design process employed by architect João Filgueiras Lima, aka Lelé; and the logical interaction among these components is a purpose he cultivates with obstinacy. His work, especially in hospitals, reflects a high alignment of construction systems to favor building efficiency. In this article, I comment on some of these contributions from my own point of observation, since I had the opportunity to be a witness, a collaborator, and even an associate in most part of such production.

Key words

João Filgueiras Lima, Lelé, construction system, structure, technical installations.

Structure and infrastructure

Among Le Corbusier's five points defining the new architecture, the open plan was certainly the one that enabled the greatest gain for modern and contemporary healthcare facilities (HF).

In fact, by detaching the structure from partitioning and sealing walls the longevity and efficiency of hospital buildings increased - either because it is easier to relocate internal spaces to incorporate new technologies for diagnosis and treatment, or to adjust to new medical techniques, or even to expand the building in an orderly fashion without interrupting medical activities during construction.

However, for the buildings to acquire effective flexibility, it is desirable to plan technical facilities with the purpose of offering the same freedom provided by the independent structure.

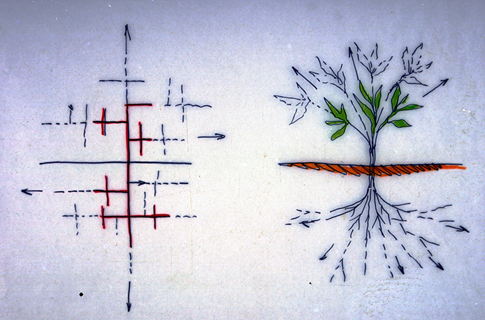

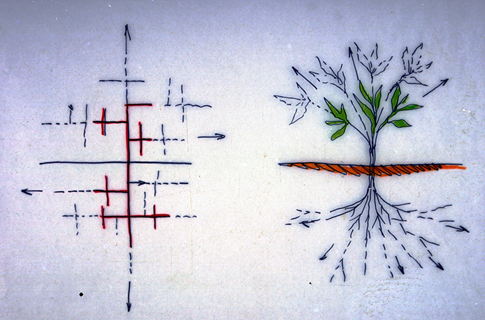

In healthcare facilities design, we observe the strategy of architects who align or associate structure and facilities - like public facilities bordering the roads that structure the city and follow them from the planned urban expansion to secondary local roads that eventually are incorporated to the project. Or just as tree roots ensure progressive and proportional stability and nourishment to the growth of leafy branches.

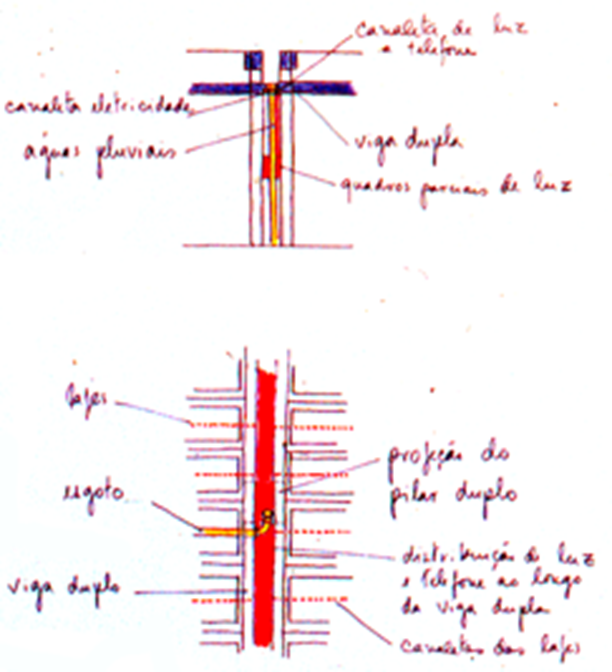

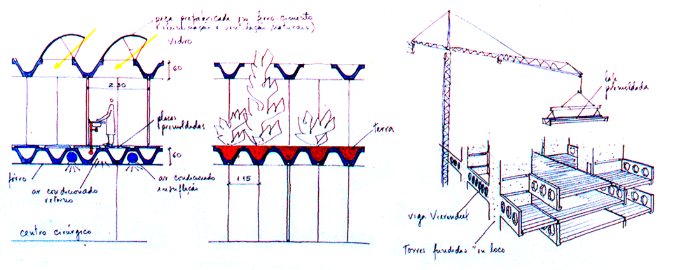

Illustration 1: Hospital expansion - structure and infrastructure; João Filgueiras Lima drawings (personal collection).

Such a comment was to introduce architect João da Gama Filgueiras Lima - aka Lelé, one of the architects who most researched and carried out technical and construction solutions that ensured flexibility and expansibility to buildings serving several purposes, mainly healthcare facilities.

First professional steps, first healthcare facilities

Lelé graduated at the end of 1955 from University of Brazil National School of Architecture (now UFRJ); he perfected his design and construction skills with architect Aldary Toledo, in Rio de Janeiro, and with Oscar Niemeyer, during his experience in Brasília.

Between 1962 and 1965, he was part of the group that founded the Architecture course at the University of Brasília, initially as professor of Construction Technique, then as coordinator of the post-graduate course and executive secretary of the UnB Planning Center (CEPLAN). He developed and detailed Oscar Niemeyer's projects for the campus, such as CEPLAN and Arts Institute buildings, the Central Science Institute (ICC, or "Minhocão") and others of his own authorship, such as the Colina housing buildings and General Services blocks - always using prefabricated solutions, industrially or on site, both to Niemeyer's designs and his own.

In 1963 he traveled to Eastern Europe to study prefabrication, and in 1969 to Western Europe and the USA to perfect his hospital planning skills.

In 1968 he conceived his first hospital design: Taguatinga Regional Hospital (TRH) - prior to that he had only designed the project for the expansion of Brasília District Hospital, originally designed by Oscar Niemeyer.

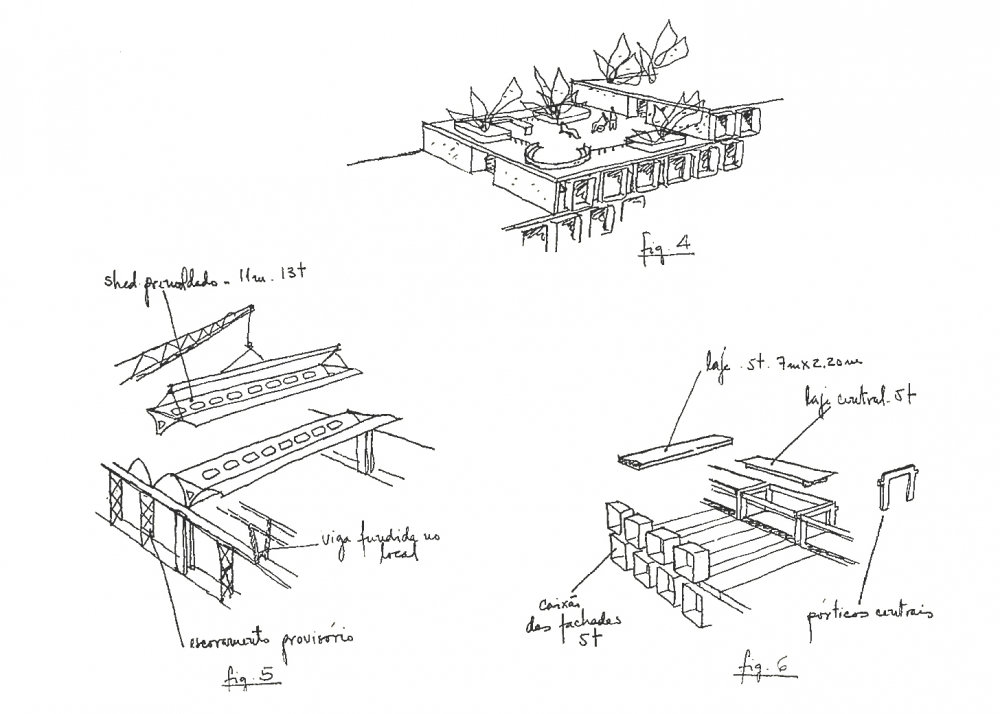

For TRH, he successfully associated his prefabrication and hospital planning knowledge, combining structure and infrastructure solutions to ensure flexibility and expandability. As Lelé himself noted, "the level of industrialization established for the construction of this hospital was quite ambitious for the time" (LIMA, 2012).

The concrete "V-shaped" beams used in TRH are like those used in Disbrave automobile shops in Brasília (1965) - but here incorporating accessible ducts at the base of the beam for distribution of various wiring, instead of conduits.

The project also presents solutions for reducing energy consumption and the use of air conditioner, favoring natural alternatives for reducing the thermal load on the façades and for zenithal illumination and ventilation, as well as for landscaping integration in internal environments - solutions that have characterized his professional activity from the beginning and endured.

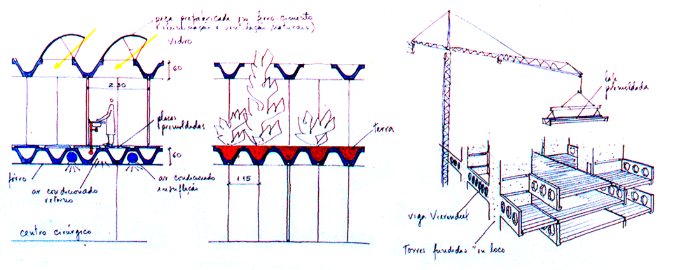

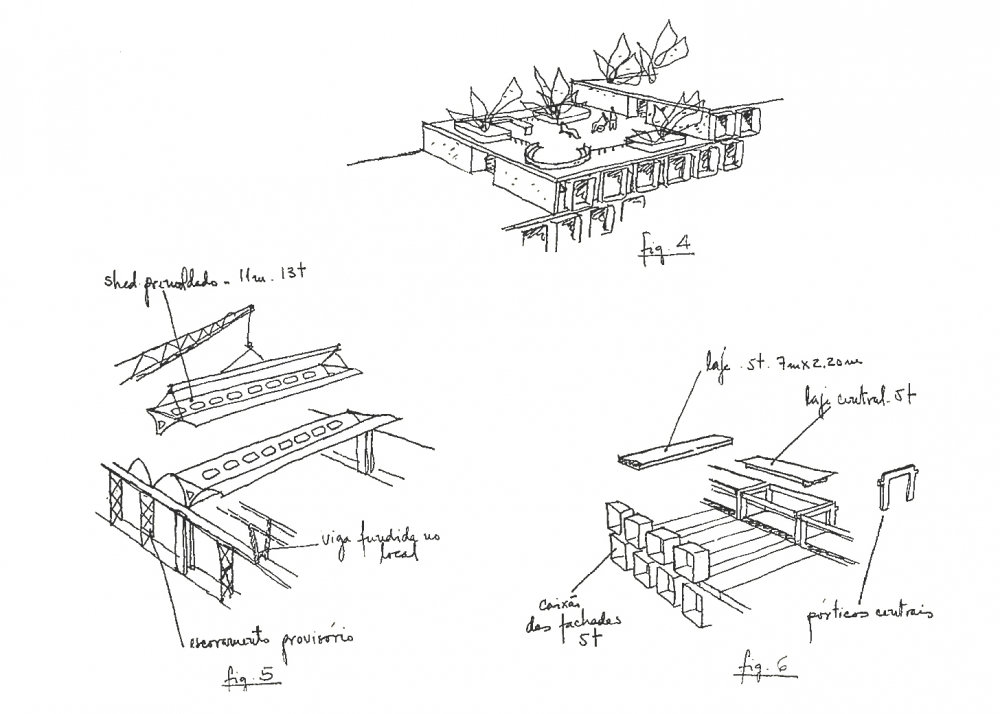

Illustration 2: A piece of the preliminary design for TRH; Illustration 4: Nurse station balconies, horizontal extensibility outlook; Illustration: Shed beams assembly, application of concrete on beams on site; Illustration 6: Vertical hospitalization block assembly - João Filgueiras Lima drawings (personal collection).

Between 1969 and 1972, as a technical consultant for Distrito Federal Hospital Foundation, he coordinated the work on the TRH, excellently executed by the then young engineer Joaquim Ferreira Cambraia, and elaborated the preliminary project for Brasília Base Hospital (BBH) - a project not carried out by DF government, which chose to "promote" the District Hospital to Base Hospital (after extensions and renovations carried out by an office with no connection to the original author of the design).

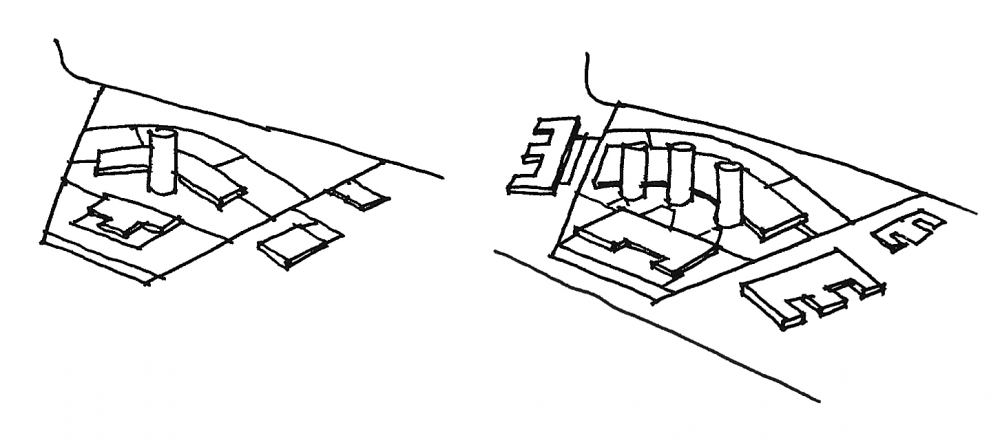

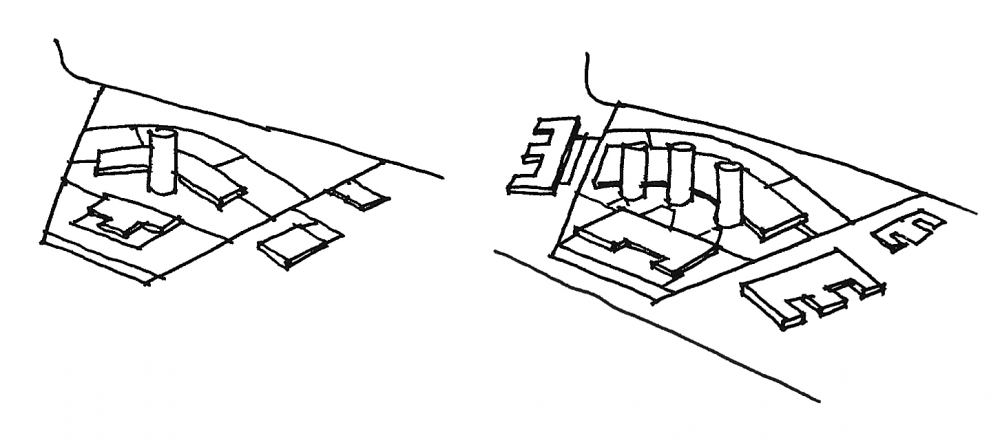

Illustration 3: A part of BBH preliminary design - on the left, 1st phase with foundation and a hospitalization tower for 600 beds; to the right, the final phase, with broaden foundation and three towers, adding up to 1,800 beds - João Filgueiras Lima drawings

(personal collection).

Sarah/DF

In the 1970s, Lima began a successful partnership with physician Aloysio Campos da Paz Jr., then director of Sarah Kubitschek Rehabilitation Center - initially to build the Musculoskeletal System Hospital (Sarah/DF).

At this stage, in addition to the control he always sought to exert over projects and their respective works, Lelé also oversaw the design of fixed and moving furniture for the hospital teamed up with designer Alex Chacon, from his UnB days.

Later on, during the expansion of Sarah Hospital Network, he would also carry out projects for several other components of the buildings, assuming wide and effective control over the new buildings: design, construction, settling, maintenance, post-use evaluation,

updates and expansions.

After this contextualization, I shall resume my topic: if in the initial projects the structure design already incorporated the path of some technical installations, in Sarah/DF we observe a constructive system that didactically integrates structure and installations.

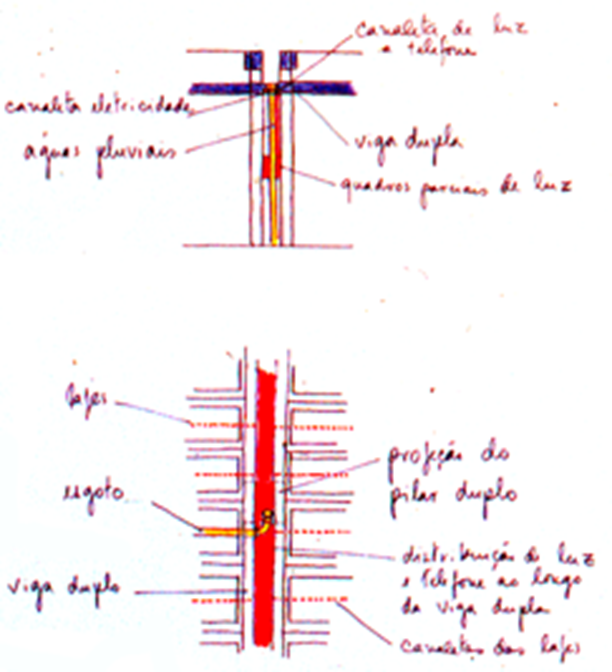

Illustration 4: Sarah/DF - basic structural system with installation traffic: on top, a cut through the double beam and double pillar view; bellow, ceiling plant - João Filgueiras Lima drawings (personal collection).

In this hospital, prefabricated concrete slabs ribbed in a symmetrical "V" shape, connected to double orthogonal beams cast in situ and on double columns, form the structural system of the hospital's basement - this one scaled in three levels, for adaptation to the terrain: 0.00 m (from the main access); -3.65 m; and -7.30 m.

At the base of the "V" ribs, the incision is maintained for the inlay of metallic channels where the wiring runs and where light fixtures or sound and detection equipment is fixed (like the solution tested in Taguatinga Hospital).

The plumbing systems are installed in the upper bed of the ribbed slabs and double beams; and in the lower "caves" of the ribs the air conditioning ducts are fitted (where necessary).

Between the double pillars, pipes from the double beams go up or down and electricity or voice and data panels are installed, establishing the general system and ordering for the transit of various installations.

Illustration 5 and 6: Sarah/DF - ribbed slabs with ducts for wiring; double beams and columns for the passage of diverse installations

(personal collection).

In the vertical block, the eight towers (which serve the vertical circulation and sanitary environments) support Vierendeel beams, which, in turn, receive the same precast ribbed beams, here composing the six floors of the Admission and medical residency block.

Illustration 7: A part of Sarah/DF preliminary design - on the left: V-shaped ribbed slabs - with passages to hydro sanitary installations, air conditioner, several wirings - it constitutes slabs, sheds, pergolas, hanging gardens; on the right: hospitalization vertical block assembly - João Filgueiras Lima drawings (personal collection).

The vertical transit of the installations in the admission block is done by shafts organized in sets of metal cabinets located in the towers supporting the Vierendeel beams, these alternately positioned to build the nurse station balconies.

Complementing the system there are an engine room to house fan+coil air conditioner units next to the surgical center (level -3.65 m); installation galleries (level -7.30 m) under the Laboratory and Image Center; and the main gallery for distribution of installations (level -10.05 m) under the General Services block and installation centers.

The work was carried out by engineer Joaquim Cambraia, like in TRH, and with equal care. Inaugurated in 1980, it has undergone adaptations and expansions over the last 40 years, without disturbing the hospital's daily activities. This constructive solution was also used with improvements and small variations in other private and public HFs planned by João Filgueiras Lima.

Group Sarah: a network of hospitals

The plan for the expansion of Sarah Hospital Network was prepared by a broad and specialized team, whose core was formed by physician Aloysio Campos da Paz Jr., economist Eduardo de Mello Kertész and architect João Filgueiras Lima.

After Distrito Federal hospital, the next facilities would be constructed in Salvador (Bahia), São Luís (Maranhão), and Curitiba (Paraná). Designed in an innovative lightweight prefabricated system in reinforced mortar, they were supposed to be produced by Salvador's Community Equipment Factory (CEF), which was overseen by Lelé at the time.

Illustration 8: Sarah/BA (1st version) - prototype of the industrialized reinforced mortar system (in the photo, beams, shingles, sheds, and sheds covers, without the pillars), produced by CTRS for the original project - Photograph: Haroldo Pinheiro

(personal collection).

Several problems hindered the beginning of the construction in 1988, so Salvador project was only resumed in 1991, when CEF was no longer available. Without a factory to produce such a volume of reinforced mortar precast, the team had to study different construction systems to adapt the original project.

The hospital in São Luís was adapted to precast reinforced concrete by the office of a local former collaborator, with the author's consent. The one in Salvador was adapted by my office, also with Lelé's consent; and, in this case, we opted for a light steel structure, which could be assembled on top of the industrialized underground galleries in reinforced mortar, which had 70% of the parts manufactured for the previous project available.

The versatility of the metallic structure and its link to the original galleries enabled the technical and economic association between structure and installations, as planned in the original proposal.

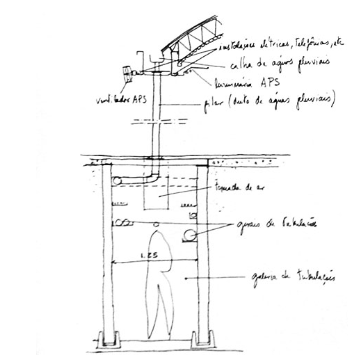

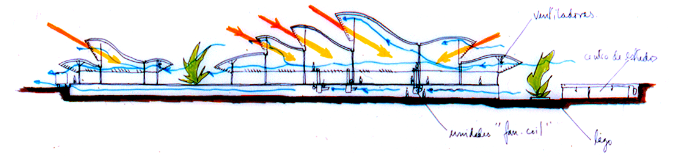

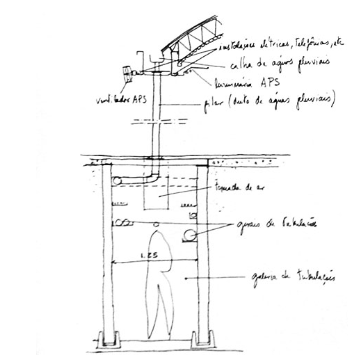

The design - in horizontal plan, in two levels to adapt to the terrain - foresaw a large network of galleries under the building. This number of technical corridors was made economically feasible by the construction process designed by Lelé: light reinforced mortar pieces, with low material consumption (panels 2.5cm thick) and manual assembly.

Besides the construction process, the triple function planned for the galleries also contributed to their viability: (1) as a ventilation and air conditioning system; (2) as a technical floor for installations and maintenance; and (3) as foundations for the building.

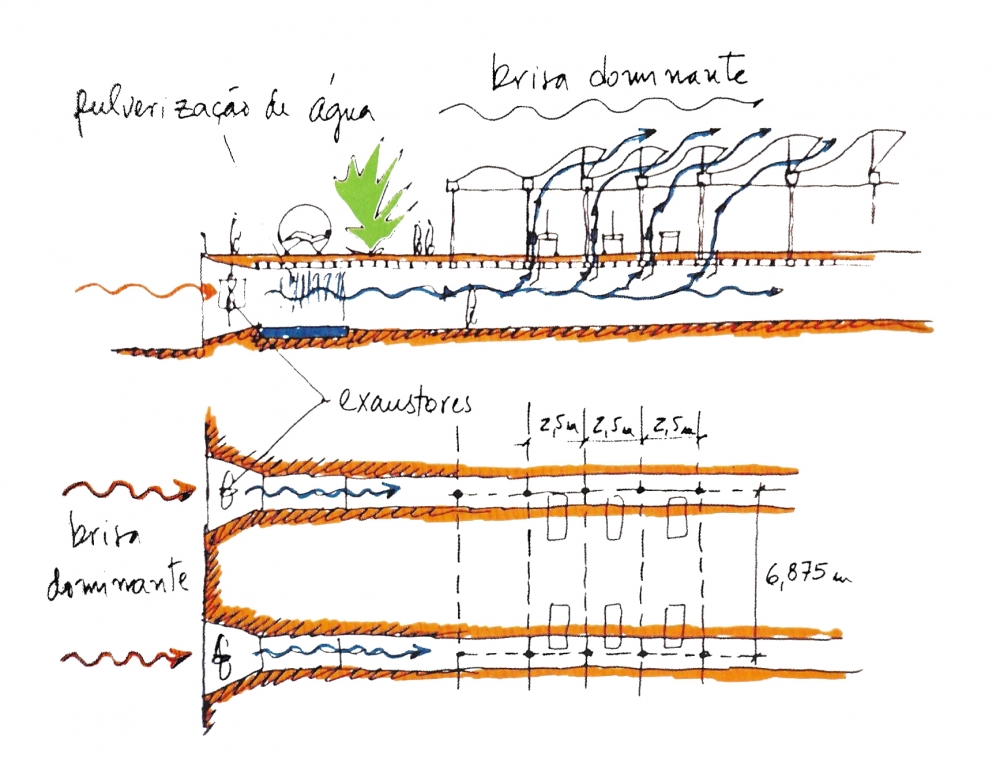

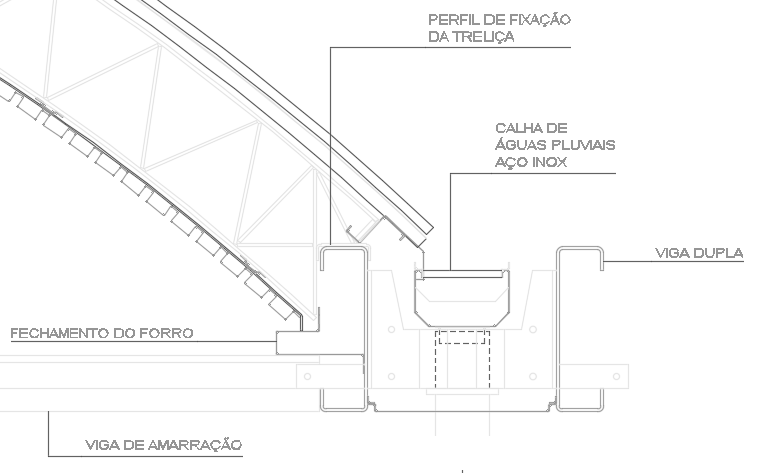

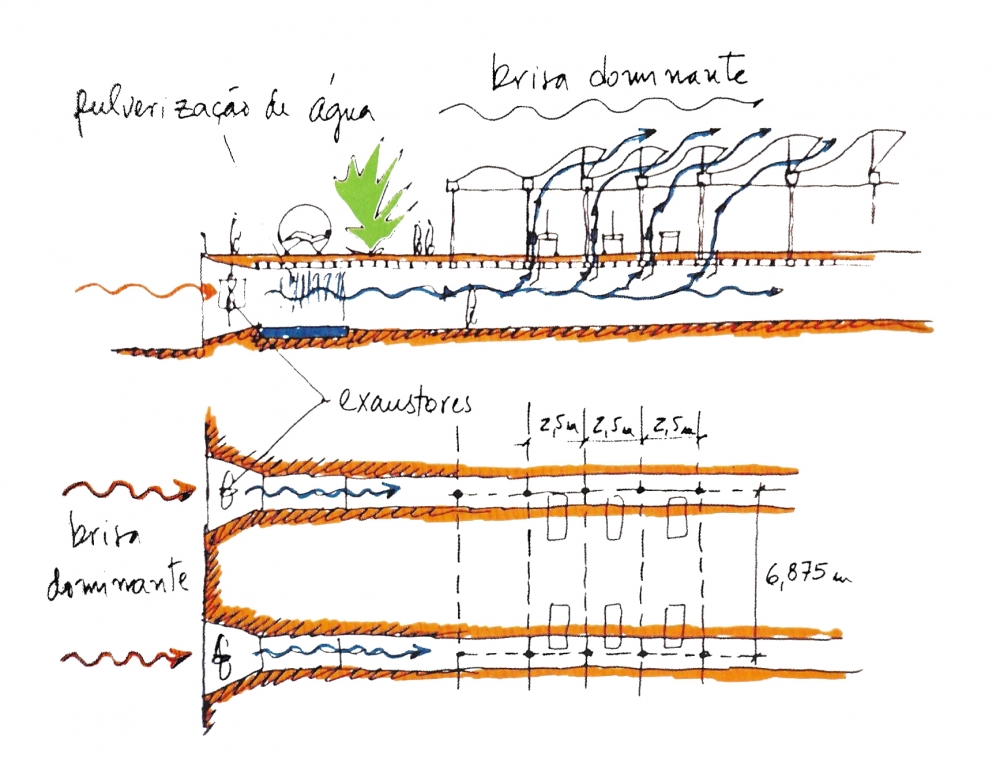

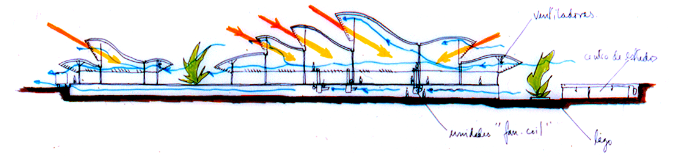

Illustration 9: Sarah/BA - natural and forced ventilation system: bellow, gallery plants (partial); on the top, longitudinal cut in the gallery and in the superior structure with a shed-shaped cover - João Filgueiras Lima drawings (personal collection).

(1) The galleries face the prevailing winds and have low rotation exhaust fans that are automatically activated when there is a reduction in the speed of the breeze; recirculating water sprinklers are used to filter particles suspended in the air and to reduce its temperature; shell catchers direct the air to cabinets with diffusers that inject the air into the upper rooms that do not require strict temperature control; and the air is drawn through the sheds, by convection and suction.

(2) The clean installations are distributed on the ceilings and on one side of the gallery, keeping a free passage for maintenance personnel; the sanitary sewage installations go outside the gallery, visitable through hermetically sealed side windows; in places where the upper environments require air conditioning, machine rooms are built next to the galleries (with the same panels) to house the fan+coil units.

Illustration 10: Sarah/CE - transversal cut in the installation/ventilation/foundation galleries with new metallic structure - João Filgueiras Lima drawings (personal collection).

(3) The gallery roofs have receptacles for tubular steel columns (also rainwater passages) and the vertical side panels are mounted on

a sliding foundation.

Illustration 11: Sarah/BA - gallery network with dentils to assemble tubular pillars - Photograph: Haroldo Pinheiro

(personal collection).

Arranged under several environments, the galleries allow the facilities to be reorganized according to new needs. The various pipes go up through the voids in the prefabricated reinforced mortar partitions (two "U" shaped panels, opposing each other, with a horizontal modulation of 0.625 m) or through technical cabinets (electricity, voice and data, hydrants, etc.) that replace partition modules when necessary.

Illustration 12: Sarah/CE - plan of reinforced mortar partitions: panel thickness = 2.5 cm; total assembled width = 25 cm - Haroldo Pinheiro drawings (personal collection).

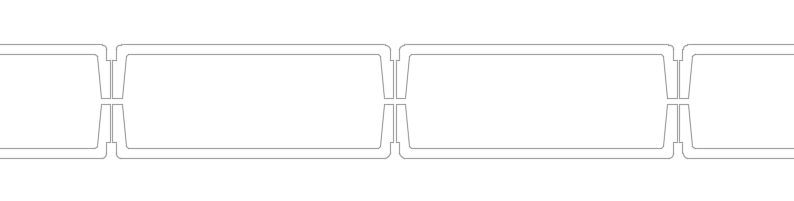

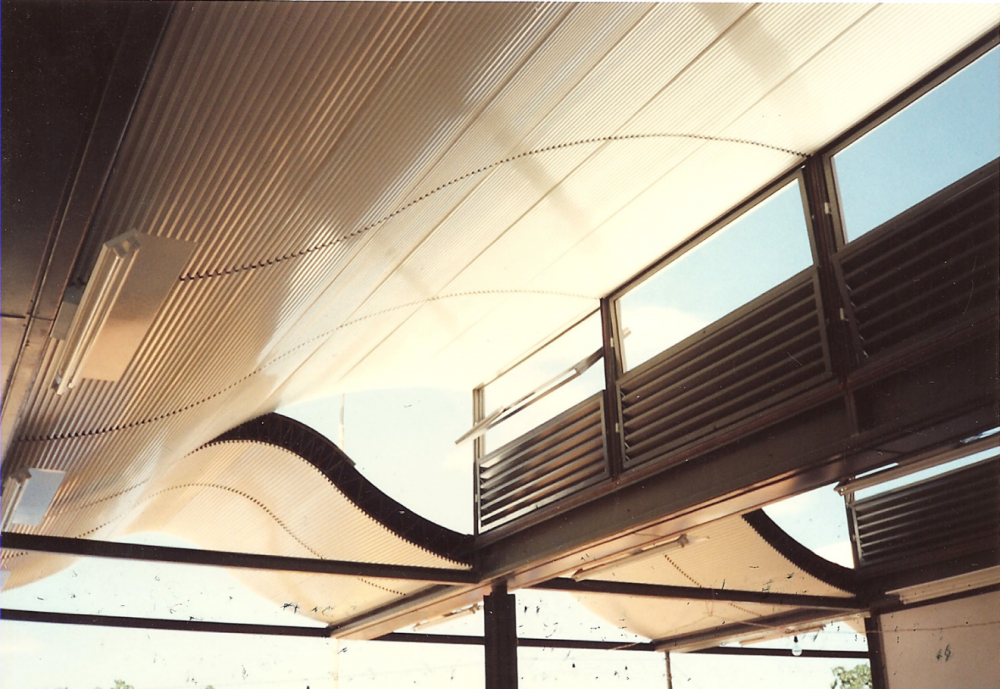

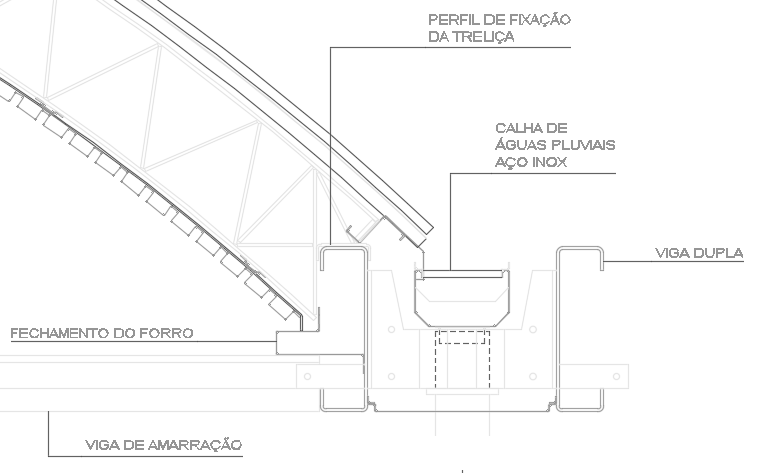

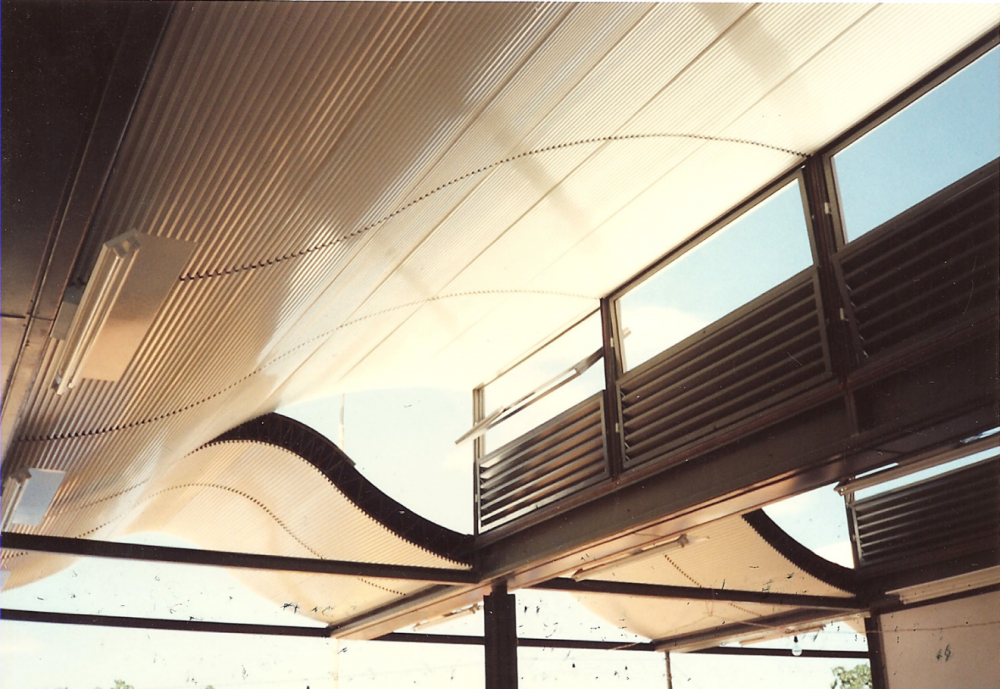

The wires reach the metallic structure of the roof and pass horizontally through channels formed in the double steel beams (in stiffened "U" shape, lying) and in the orthogonal tie beams (designed in stiffened "U" shape, juxtaposed to the walls). Lighting fixtures, speakers, fans, detectors, and other elements attach to the double beams or to the tie beams.

Illustration 13: Sarah/BA - assembly of double longitudinal beams and transversal tie beams - Photograph: Haroldo Pinheiro

(personal collection).

The double beams house stainless steel gutters for collecting rainwater, which flows down the tubular pillars and into the galleries for reuse.

Illustration 14: Sarah/CE - detail of the double beam, lower gutters for wiring (cross section) - Haroldo Pinheiro drawings (personal collection).

The arches of the roof are used to pass the air conditioning ducts, whenever necessary (Surgical Center, Imaging, Laboratories, Auditorium).

In the rest of the hospital, where air conditioner is not technically required, the closed roof is replaced by sheds that provide natural lighting and a vertical flow of cooled ventilation from the galleries, replacing cross ventilation.

Illustration 15: Sarah/BA - double beams with attached light fixtures, tie beams and roof being assembled: foreground with shed; background, without shed (for balconies and air-conditioned rooms) - Photograph: Haroldo Pinheiro (personal collection).

After Sarah/BA, Lelé planned and implemented Sarah Network Technology Center (SNTC), also in Salvador, where for twenty years he produced and assembled hospitals and other public buildings; urban equipment (footbridges, slope retaining systems, urban furniture); fixed and moving hospital furniture; and other equipment for buildings designed and built by SNTC (elevators, locks, fans/exhausters, lighting fixtures, loudspeakers, "brise-soleil" with automatic movement, retractable roofs).

The solution studied for Salvador, despite being an adaptation of the project originally designed for industrialization in reinforced mortar, worked well and evolved, welcoming the necessary variations to adapt to other characteristics of the locations, such as topography, lot dimensions, climate conditions.

Moreover, other hospitals were built in Belo Horizonte, Fortaleza, Belém, Brasília, Macapá, and Rio de Janeiro, in addition to extensions for Distrito Federal's facility, also under my office's coordination. Two further hospitals were designed using the same system, for Pernambuco and Rio Grande do Norte, whose construction has not yet been carried out.

The hospital in Rio de Janeiro (Sarah/RJ), built by SNTC and carefully assembled by architect Adriana Rabello Filgueiras Lima, was the last healthcare facility designed by Lelé.

Illustration 16: Sarah/RJ - aerial view and drawings by João Filgueiras Lima

(personal collection).

It was a personal and deliberate choice not to include Rio de Janeiro's hospital design in this brief article, since I consider it a special and different chapter in João Filgueiras Lima's work evolution - it certainly deserves a dedicated article.

Reference

LIMA, João Filgueiras. Arquitetura: uma experiência na área da saúde. São Paulo: Romano Guerra Editora, 2012. 336p.

About the author

Haroldo Pinheiro Villar de Queiroz is an architect graduated from Brasília University Institute of Arts and Architecture (IAA/UnB, 1980). He has worked as João Filgueiras Lima's (1976/2014) collaborator and associate; and as technical consultant for Associação das Pioneiras Sociais/Sarah Hospital Group (1988/98). He was ranked first at the Public Architecture Bid for Guará Regional Hospital (1989). Finally, he was IAB national president (2000/04) and is president and founder of CAU/BR (2011/17).

Send by e-mail: